Flange joint is one of the key components in many engineering industries. They are utilized for joining pipes, valves and equipment. We have different sizes flange connectors depend on your requirements.

Here are some important factors to consider when selecting flange connectors for your application. For one, it’s going to depend on the size of pipes or equipment you are connecting. Flange connectors sizes vary, so select by specific size to ensure a proper fit. Also thow there is always the factor of what the flange connectors are made out of and how they hold up. Everything from the flange connector itself is provided ranging from stainless steel, carbon steel or PVC ones –it depends on the material that is best suited for what you need them for! Lastly, consider the pressure and temperature needs of your application. Ensure the flange connectors you select can withstand your pressure/temperature conditions for a safe and efficient process.

Flange connectors often suffer from leakage. If no leaks are observed, those might be caused by mist of reason to worry like not properly installing the showerhead or old washers or corrosion if you see some. To resolve this problem, verify that the flange connectors are securely aligned and tightened. Replace pitted gaskets if necessary, and consider using flange connectors that won't corrode. Another thing that tends to be a problem is alignment, which will cause strain on the connections and possible leaks. To overcome this misalignment problem, be sure that the piping or equipment is precisely aligned before the flange connectors are installed. Also, use those metal flange connectors with wavy outer edges; they can flex when needed and you will not have any trouble in the future. Once these most common questions (and not so common ones) are answered, along with selecting the proper flange connectors for your application, you will pave the way to prompt and efficient operation in your industrial applications.

In industries, flange connections are integral for secure and leak-free connection of pipes or machineries. An important feature of the flange connectors is that they are typically designed to resist high pressure and temperature, which seems suitable for industrial applications. In addition, flange connectors provide the advantage to be assembled and disassembled readily as required in maintenance/repair purposes. They can also compensate for angular misalignment and accept tension, compression, and shear movement without breaking down in the joint. In general, flange connectors are indispensable to industrial processes in order to secure that these run effectively and reliable.

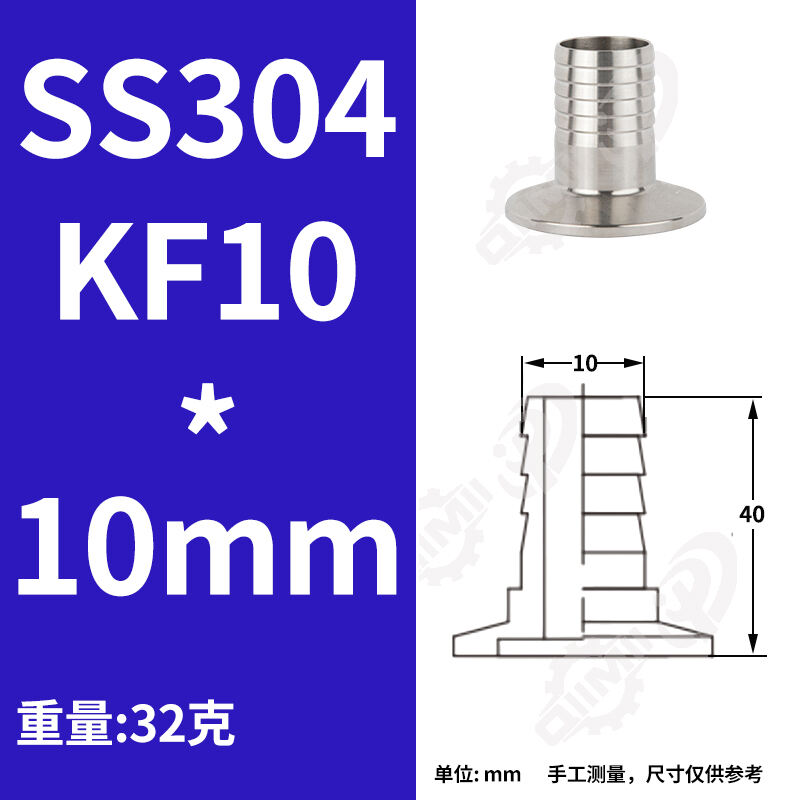

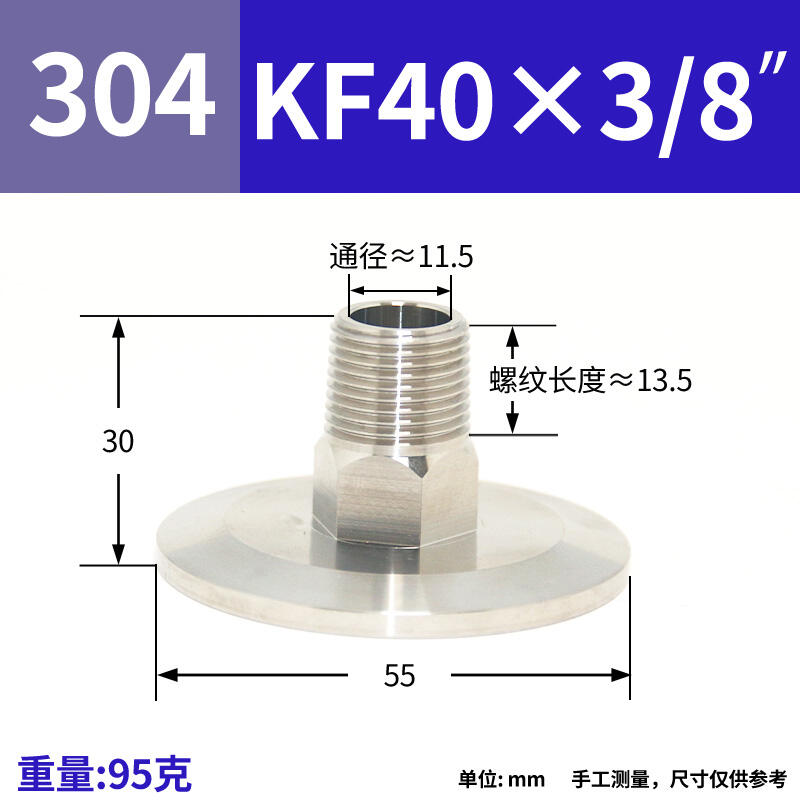

When selecting the best flange connectors for industrial applications, QiMing is one of the greatest suppliers available. Flange connectorConnectors available in various sizes, made of strong materials including SS304, carbon steel, and alloyed steel to provide a durable performance under harsh conditions.. Their range of flange connectors are available in a variety of sizes, pressure ratings and terminations to suit the requirements of differing industrial uses. In addition, QiMing also offers best in class support to help you select the correct flange connectors for your needs. When you choose QiMing as your provider, you can be assured that you’re receiving high-quality flange connectors for maximum performance and durability.

Our products hold ISO 9001 certification and 3A sanitary certification, with fully traceable raw materials and rigorous quality control throughout production, ensuring compliance with international standards for hygiene, safety, and durability.

Equipped with Mazak CNC machines, milling CNC centers, handheld spectrometers, and advanced helium mass spectrometer leak detectors, we guarantee precision machining and zero-defect sealing for critical vacuum and high-purity applications.

We specialize in manufacturing stainless steel valves and fittings tailored for demanding industries such as food & beverage, dairy, cosmetics, pharmaceuticals, semiconductors, solar energy, and lithium technology, ensuring material compatibility and performance reliability.

With a 1,500 sqm storage area and products exported to over 25 countries—including the USA, UK, Germany, Japan, and Australia—we maintain ample stock and efficient logistics to ensure timely delivery and reliable supply chain support worldwide.

Copyright © Wenzhou QiMing Stainless Co., Ltd. All Rights Reserved - Privacy Policy - Blog