Ultra-high purity fittings are critical components in a wide variety of industrial applications. These connections are constructed to stringent standards for cleanliness and chemical composition, making them well-suited for applications in clean rooms or laboratories as well as in food and beverage handling or semiconductor manufacturing. QiMing has a full line of high quality pumps ideal for any application or industry.

When it comes to industrial applications, the selection and application of high-purity fittings are critical for ensuring machine processes as well as production that demands liquid and gas control. They are also contamination free and purity required which is especially desirable for industries handling pure chemicals where an impurity may be detrimental. For instance, the pharmaceutical industry utilizes high purity fittings in manufacturing drugs and vaccines, where even the slightest impurity could affect safety and efficacy of the product that is available at the end. Employed in the same semiconductor industry, where one single particle can cause a microchip failure, you do not want after all those painstaking efforts, any impurities coming to your products when performing these high purity fittings. Use of FDL Ultra VCR & QCR Fittings in industrial applications allows companies to reduce the chances of contamination, minimize product quality and increase overall operational efficiency.

Working with high purity fittings provides benefits that allow to increase productivity and efficiency, reduce downtime opportunities, while keeping the safety standards of final products at a reasonable level. One of the main benefits of high purity fittings is their ability to preserve the purity and cleanliness of the components being utilized, which is critical in sectors where any contamination can be potentially hazardous. Through the use of high purity fittings, companies are able to limit contamination exposure, decrease the amount of time and money required for maintenance costly repairs needed down the road as well as improve their overall process flow. Furthermore, fittings of high purity are engineered to withstand the rigors of particle-free systems providing an assured, long-term performance. In conclusion, adding high purity fittings to your processes will help you meet industry demands, improve product quality and remain competitive in the fast moving industrial world of today.

QiMing the name to trust for high purity fittings. Our high purity products are the top-of-the line in quality and competitive pricing on the market, bringing you t he perfect fit for industries that require systems that deliver a peak performance of unparalleled clarity and cleanliness. QiMing manufactures high purity fittings for demanding users in the pharmaceutical, biotechnology, food and beverage, and microelectronics industries.

The most important advantage of using QiMing’s high-purity fittings is the efficiency they will bring to your production line. Thanks to our high precision design and tight tolerances, the greater work quality of our high purity fittings prevent the risk of contamination and allow your media to seamlessly run through all lines. Not only does this enhance overall production quality, but it also cuts downtime and maintenance costs, maximizing business productivity and profit.

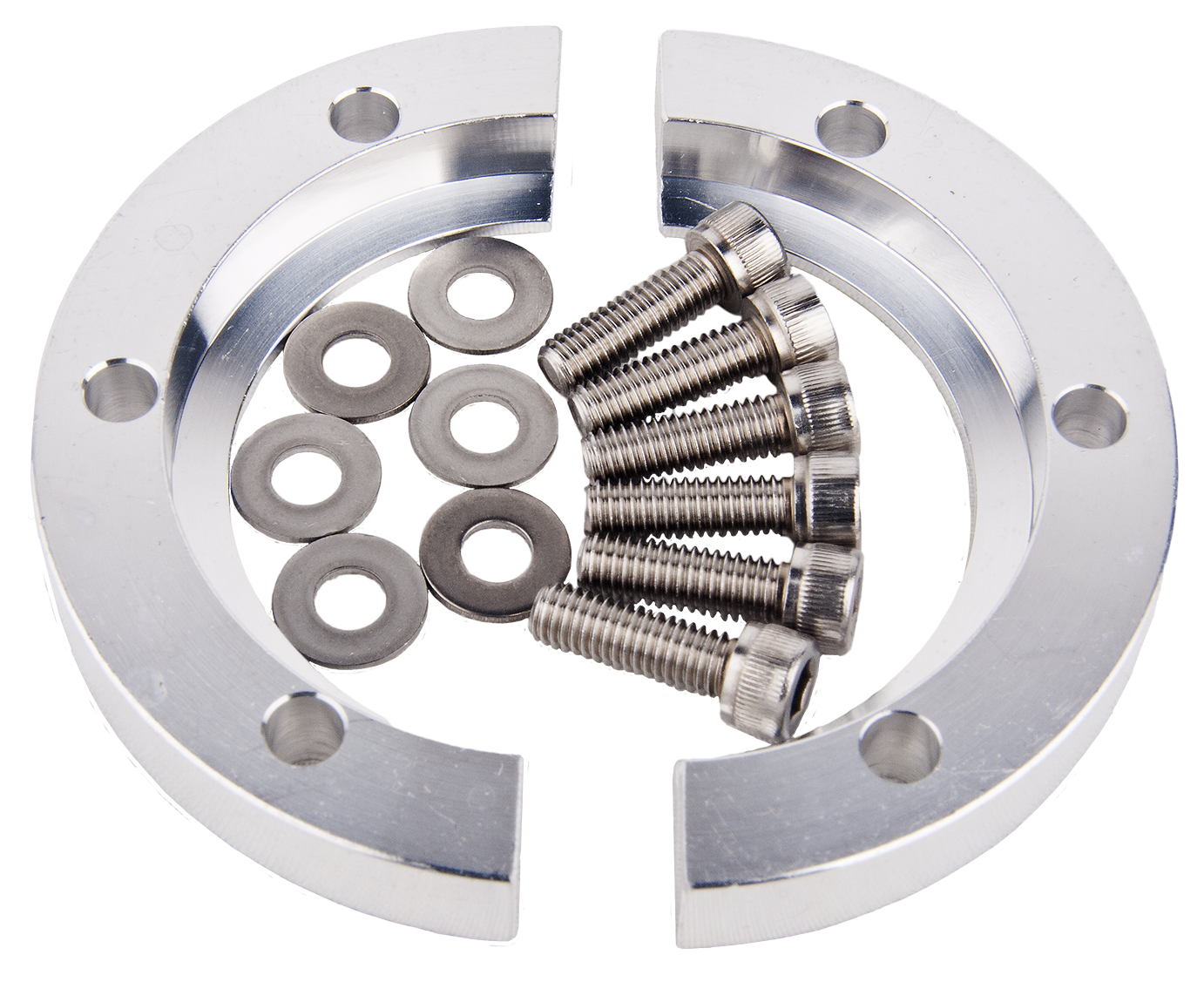

We specialize in manufacturing stainless steel valves and fittings tailored for demanding industries such as food & beverage, dairy, cosmetics, pharmaceuticals, semiconductors, solar energy, and lithium technology, ensuring material compatibility and performance reliability.

Equipped with Mazak CNC machines, milling CNC centers, handheld spectrometers, and advanced helium mass spectrometer leak detectors, we guarantee precision machining and zero-defect sealing for critical vacuum and high-purity applications.

With a 1,500 sqm storage area and products exported to over 25 countries—including the USA, UK, Germany, Japan, and Australia—we maintain ample stock and efficient logistics to ensure timely delivery and reliable supply chain support worldwide.

Our products hold ISO 9001 certification and 3A sanitary certification, with fully traceable raw materials and rigorous quality control throughout production, ensuring compliance with international standards for hygiene, safety, and durability.

Copyright © Wenzhou QiMing Stainless Co., Ltd. All Rights Reserved - Privacy Policy - Blog