When you work in an industry, it is essential that you use the proper fittings to get the work done as efficiently and effectively as possible. For that, there have been QiMing’s KF25 NW25 fittings. Designed for use in a variety of industrial applications, these fittings can safely and reliably connect types of systems. Suitable for use with a range of applications, ranging from vacuum systems to semiconductor manufacturing. So, let’s take a look at the advantages of using these fittings with your industrial applications.

Cons of Using KF25 NW25 Fittings While the KF25 NW25 vacuum fittings are pretty great, there are a few issues that users may face. The last thing you want is inefficient or leaky heating after all. Care has to be taken to strictly adhere to manufacturer instructions when installing the fittings, so they are not cross-threaded and firmly tightened. Another typical problem is with-component compatibility. KF25 NW25 fitting is not universal and varies from manufacturer to manufacturer, it also mean some of the parts using KF25 NW25 are might not be compatible with each other so please check before making any connecting process. Furthermore, to ensure that the fittings are working properly and will not cause any future issues they need to be regularly maintained and checked. You can avoid such common usage problems by taking the following steps and make sure you get the best quality of KF25 NW25 fittings in your industries.

In the industrial process world, efficiency is critical. A significant aspect that is involved in the efficient of the system is the use of precision parts like KF25 NW25 fittings. These couplings are necessary in order to create airtight connections between separate parts of vacuum systems, so that gases or fluids can be passed through without any leakage. Industrial applications can run at maximum efficiency with KF25 NW25 fittings, reducing the possibility of downtime and ensuring that projects are completed as soon a possible.

How to Store KF25 NW25 Fittings The storage & handling of KF25 NW25 fittings are both critical for the quality as well as long use performance. Clean, dry and keep away these fittings when not being used so as to avoid dust or dirtying. Also, you handling these fittings gently is a must to prevent any scratches or dings which could negatively impact the air tight seal. Appropriate tools should also be used in the installation and removal of KF25 NW25 flange fittings to avoid dangerous situations such as leaks or other related circumstances.

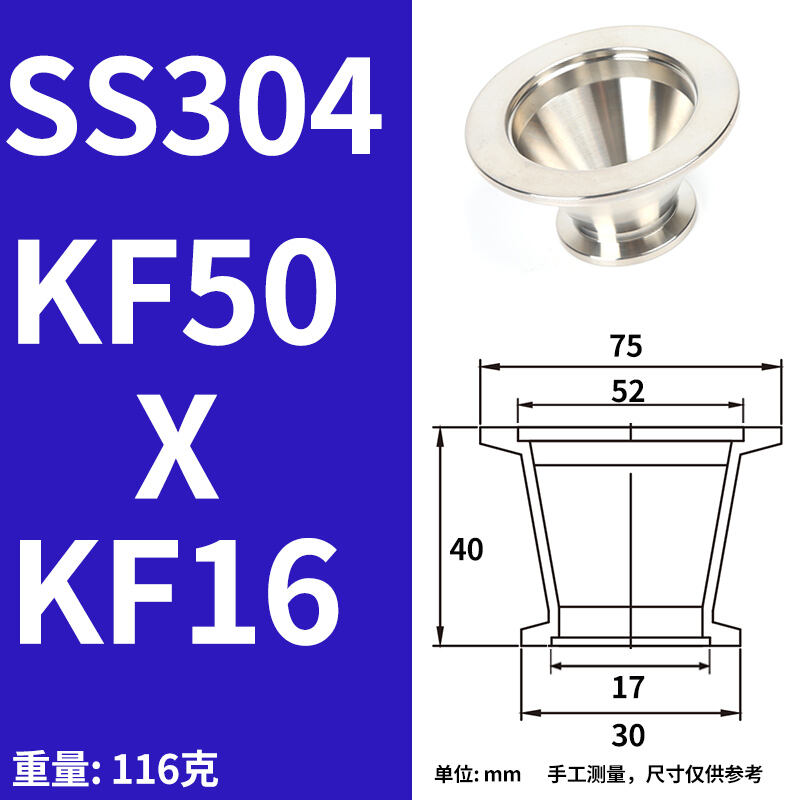

When you buy KF25 NW25 fittings, there are some important factors to consider in order to be sure that you are getting top notch items. One thing to look for is going to be materials with which the fittings are made and these things should be constructed from some solid, long-lasting materials like any of the stainless steel or aluminum. Also, make sure to inspect the fitting for machining quality and precision to seat and seal properly. Another important aspect to be looked at is the compatibility of the fittings with other vacuum system elements, as getting high performance results one should try to avoid any unnecessary connection between these. Sus 304: Powerful, sturdy and robust Culves KF25 NW25 fiting assemblies are made of premium quality SUS 304 which is not an ordinary stainless steel.

With a 1,500 sqm storage area and products exported to over 25 countries—including the USA, UK, Germany, Japan, and Australia—we maintain ample stock and efficient logistics to ensure timely delivery and reliable supply chain support worldwide.

We specialize in manufacturing stainless steel valves and fittings tailored for demanding industries such as food & beverage, dairy, cosmetics, pharmaceuticals, semiconductors, solar energy, and lithium technology, ensuring material compatibility and performance reliability.

Our products hold ISO 9001 certification and 3A sanitary certification, with fully traceable raw materials and rigorous quality control throughout production, ensuring compliance with international standards for hygiene, safety, and durability.

Equipped with Mazak CNC machines, milling CNC centers, handheld spectrometers, and advanced helium mass spectrometer leak detectors, we guarantee precision machining and zero-defect sealing for critical vacuum and high-purity applications.

Copyright © Wenzhou QiMing Stainless Co., Ltd. All Rights Reserved - Privacy Policy - Blog