Tri clamp butterfly valves are the work horse of any sophisticated brewery. These valves are applied in several industries such as: food & beverage, pharmaceuticals and chemicals. The tri clamp butterfly valve combines with a pull style handle for fast and precise flow control in applications including the brewing, pharmaceutical, or dairy industries. In the next paragraphs we will see the benefits of tri clamp butterfly valves for industrial use and their applications, and how to select an appropriate valve according to one’s needs.

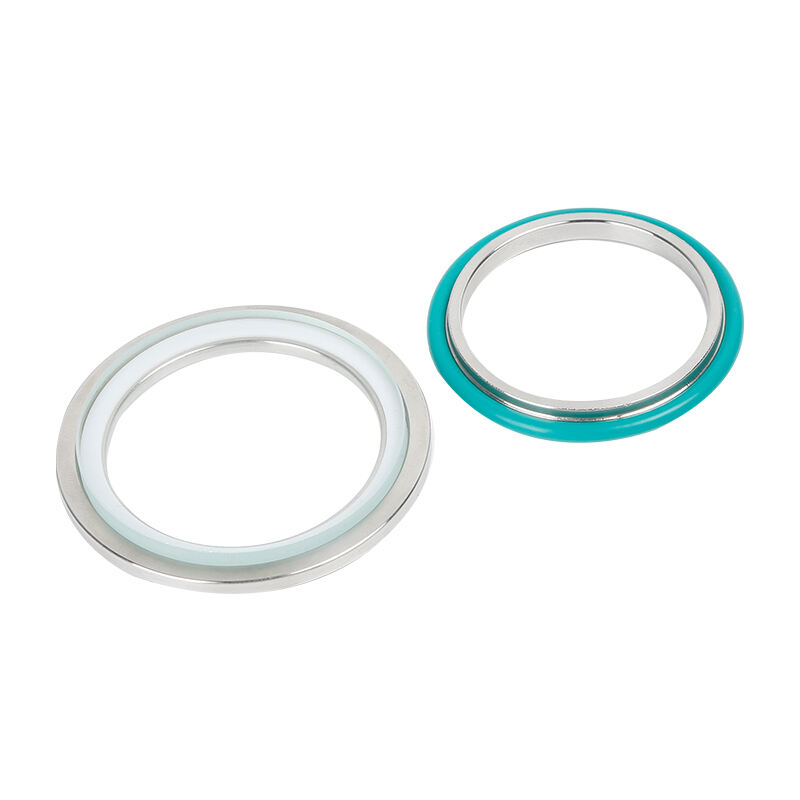

There are several benefits to using tri clamp butterfly valves for industrial applications, the main one being that they are easy to install and maintain. Our valves can be easily fitted to pipes with the use of tri clamp fittings, as opposed to other tools. The foregoing allows the valve to be replaced or serviced without requiring substantial down-time in the production process. Moreover, the tri clamp butterfly valve has a very straightforward construction that reduces leaks and prevents contamination so operations can remain safe and efficient.

Tri clamp butterfly valves are considered to achieve a sharper and more precise instrument for managing the flow of fluids and air. The butterfly disc located in the valve, directly behind the orifice plate, simply throttles to decrease flow rates – providing precision control and peak performance. This level of regulation is mandatory in applications that require predictable closure speed like food or chemical processes. Poor valve performance and/or other flow disruptions, which can diminish product quality since the final product can experience turbulence or vary in pressure.

These are also very ideal as many tri clamp butterfly valves can be used effectively with a wide range of applications. These valves comes in different sizes, material & its configuration to fit product requirements. From harsh chemicals, hot water, and sanitary fluids to the most delicate substances, there is a tri clamp butterfly valve tailor-made to the unique demands of every process. This versatility has made these valves a preferred option for many manufacturers, seeking trusted and cost-effective solutions for their industrial needs.

In addition to being easy to install, providing accurate control and being versatile, tri clamp butterfly valves are also popular for their durability and long service life. That's because they're made from a strong material that are able to handle the toughest conditions and frequent use. When treated well, these tri clamp butterfly valves can last for many years, providing excellent performance levels. And, this longevity also leads to less cost for businesses that need not buy/replacement/repair the butterfly valve every now and then hence offering good return on investment as a long term solution.

The actuation mechanism must also be taken into account when selecting a tri clamp butterfly valve. They can be operated manually, pneumatically or electrically according to degree of automation and control required. Manual valves are applicable for simple applications in which the flow rate requires changing once in a while, whereas pneumatic or electric control valves are perfect for continuous and long-distance manipulation that needs pressing control of media volume.

Finally, do not forget to take into account whether the valve is compatible with your current system and components. These clamps can be wafer type, lug type or flanged end and the valve you choose should fit perfectly with the existing system. With all of these factors in mind and after discussing your requirements with a reputable supplier like QiMing, you can easily decide on the perfect tri clamp butterfly valve for you application that will not only fit your particular needs but also improve the productivity levels of your industrial operations.

We specialize in manufacturing stainless steel valves and fittings tailored for demanding industries such as food & beverage, dairy, cosmetics, pharmaceuticals, semiconductors, solar energy, and lithium technology, ensuring material compatibility and performance reliability.

Our products hold ISO 9001 certification and 3A sanitary certification, with fully traceable raw materials and rigorous quality control throughout production, ensuring compliance with international standards for hygiene, safety, and durability.

With a 1,500 sqm storage area and products exported to over 25 countries—including the USA, UK, Germany, Japan, and Australia—we maintain ample stock and efficient logistics to ensure timely delivery and reliable supply chain support worldwide.

Equipped with Mazak CNC machines, milling CNC centers, handheld spectrometers, and advanced helium mass spectrometer leak detectors, we guarantee precision machining and zero-defect sealing for critical vacuum and high-purity applications.

Copyright © Wenzhou QiMing Stainless Co., Ltd. All Rights Reserved - Privacy Policy - Blog