SS316L Ultra High Purity Tube Long Elbows Weld Fittings UHP Automatic Orbital Elbow Stainless Steel Long Weld Fittings for Ultra-High Purity

Weld fittings are high quality, so they will perform well under a multitude of conditions, minimizing contamination or unwarranted failure. Using a proven manufacturing approach,Consistently exceeds the required performance requirements and offers exceptional results for all industries requiring weld fittings to get their jobs done.

- Overview

- Recommended Products

B Series – Tube Butt Weld Fittings

Features

* Extended tube design

* Sizes range from 1/8″ to 1/2″, and 6 mm to 12 mm

* Machined from forging blanks except for straight configurations

* Elbows with radius junction to provide smooth flow path

* Precision machined to match tube diameter

* Burr-free tube ends to enhance alignment

* 100% visual inspection on key parts under magnifier and good light conditions

* Standard surface roughness finished to an average of Ra 10 μin. (0.25 μm) or electropolished to Ra 5 μin. (0.13 μm)

* Permanent traceable identification marked on each fitting

Weld fittings are available in butt weld, socket weld, automatic tube weld and as metal gasket face seal fittings.

Weld fittings for Ultra-high purity applications

For ultra-high purity applications, Weld fittings are electro-polished and packed in triple vinyl bags in a Class 10 environment. Weld Fitting features include:

- Tapered socket weld ports to speed layout for proper tube fit and tube alignment.

- Automatic tube weld and butt weld design

- Size range from 1/8″ thru 1″ O.D. tubing

- Mini and long tube end design

Benefits

Weld fittings are high quality, so they will perform well under a multitude of conditions, minimizing contamination or unwarranted failure. Using a proven manufacturing approach,Consistently exceeds the required performance requirements and offers exceptional results for all industries requiring weld fittings to get their jobs done.

One of our representatives will gladly assist you with your production selection or answer any questions you may have regarding our fittings.

Instrument Weld Fittings

These various fittings have been strategically engineered and designed so they can serve a wide range of applications safely and accurately. These are designed to be used in chemical, pulp and paper, dairy, pharmaceutical, power generation, food, marine construction or ship building, beverage and all other kinds of industries requiring high-purity fittings. Whether your application requires 316 stainless, metric, imperial or special fitting needs,USA has what you need. Our fittings include the union, union elbow, union tee, male connector, female connector, male elbow, female elbow, pipe weld to tube socket weld, tube weld to tube socket weld and more.

About Us

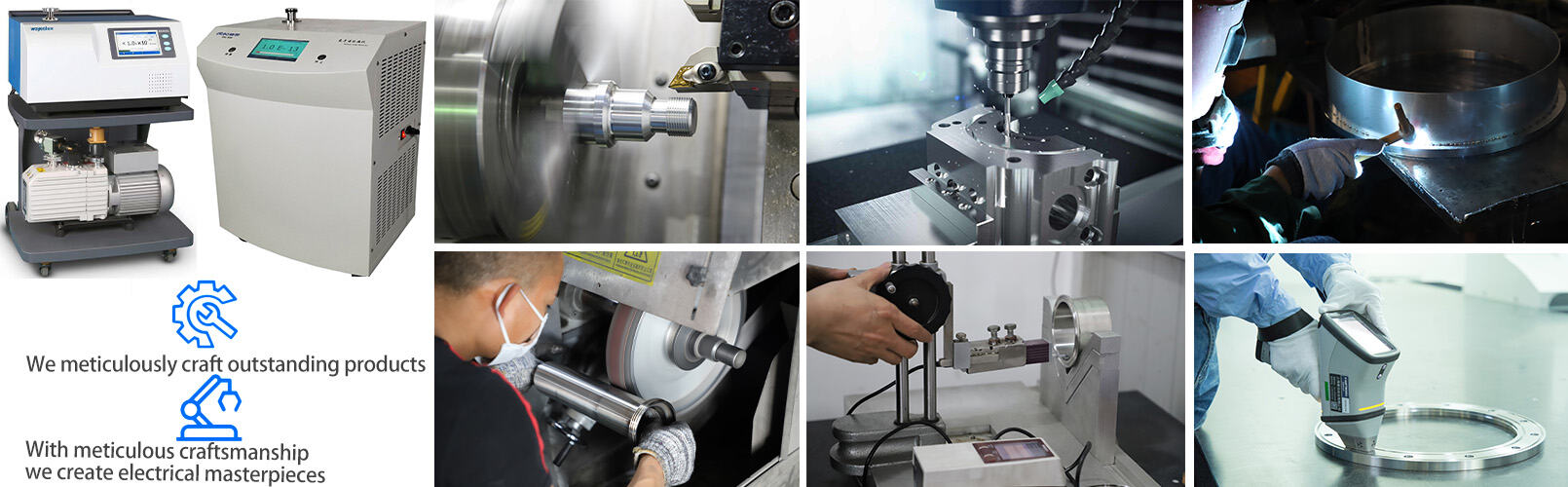

Wenzhou QiMing Stainless Co., Ltd. was founded in 2015, located in Wenzhou city providing a wide range of stainless steel valves and fittings for food, dairy, beverage,cosmetic, wine industries, semiconductor, LCD,solar energy, lithium technology, photovoltaic and other high-tech industries. mainly manufacture and export SS valves and fittings including Butterfly Valve, Ball Valve, Check Valve, Angle Valve, Vacuum Valves, Tri Clamp Fittings, Weld Fittings,KF/NW flanges, ISO Flanges and CF Flanges. has Mazak CNC, Milling CNC, handheld spectrometer,helium mass spectrometer leak detection, roughness tester and others. With more than 10 years development, QiMing gets 3A certificate and ISO9001:2008. QiMing's main market is Europen, USA, Korea,Japan and so on.

QiMing Market

Our products are exported to many countries, including South Korea, the United States, the United Kingdom, ltaly, France, the Netherlands, Finland, Russia, Belarus, Thailand, CanadaMexico,

Australia, Germany, Spain, Malaysia, Singapore, Vietnam, Indonesia, India, thePhilippines, Japan, Paraguay, Brazil, Chile, Peru, and more.

QiMing Team

Our experienced engineers work closely with each customer to find out the best possible solutions.Our constant technical innovation combined with stringent quality control systems hasenabled us to deliver high performance and outstanding value in sanitary applications.We are dedicated to improving the performance and value of our products, services, and solutions to meet your requirements

Equipment & Testing

QiMing has advanced CNC machieries,CNC centers and Testing Equipment,ISO9000 Certificated and all raw materials are traceablethe ablethe

Certificate

Exhibition

Wenzhou Qiming Stainless Steel Co., Ltd. participated in the Japan Semiconductor Exhibition in November 2023, the Shenzhen Semiconductor Exhibition in June 2024, and the U.S. Semiconductor Exhibition in July 2024. In December 2024, the company attended the Japan Semiconductor Exhibition again and participated in the China Optoelectronics Expo during the same period. It will take part in the China Optoelectronics Expo in September 2025, the U.S. Semiconductor Exhibition in October 2025, and the Japan Semiconductor Exhibition in November 2025.

FAQ

Q: Why would I choose you?

Wenzhou QiMing Stainless Co., Ltd has been engaging in manufacturing sanitary valves, fittings, tank components and pumps for over

15 years, outstanding in production capacity, effective management, accurate lead time, on-time shipments and problems-solving

rate after sales.

Q: May I have free samples before ordering?

Yes, our company is very pleased to send you free samples for quality test as long as freight cost being paid by buyers

themselves.

Q: What's the MOQ?

The majority of products are fully in stock, so we accept 1 piece as the minimum order quantity.

Q: Does your company have the export license?

Yes, we have more than 4 years export experience, we can do FOB, C&F, CIF, DDU and DDP (Russian Only).

Q: What's the payment term?

For small testing orders, we accept Paypal, Western Union, T/T and Credit Card.

For mass orders, we accept T/T and L/C.

Q: How would you minimize damages during delivery?

Standard: mass orders will be packed by many carbon boxes and filled in plywood cases.

Available requirement: blister packing for every piece of product, plastic caps for clamp connected products.

Q: How would you choose the shipment way?

Basically, we will select shipment ways based on four factors (order quantity, delivery time, costs and customs policy), then list

couples of reasonable options with Pros and Cons to customers, letting them to decide.